XM-25, UNS S45000, 1.4594, X5CrNiMoCuNb14-5, Custom 450, B50A789

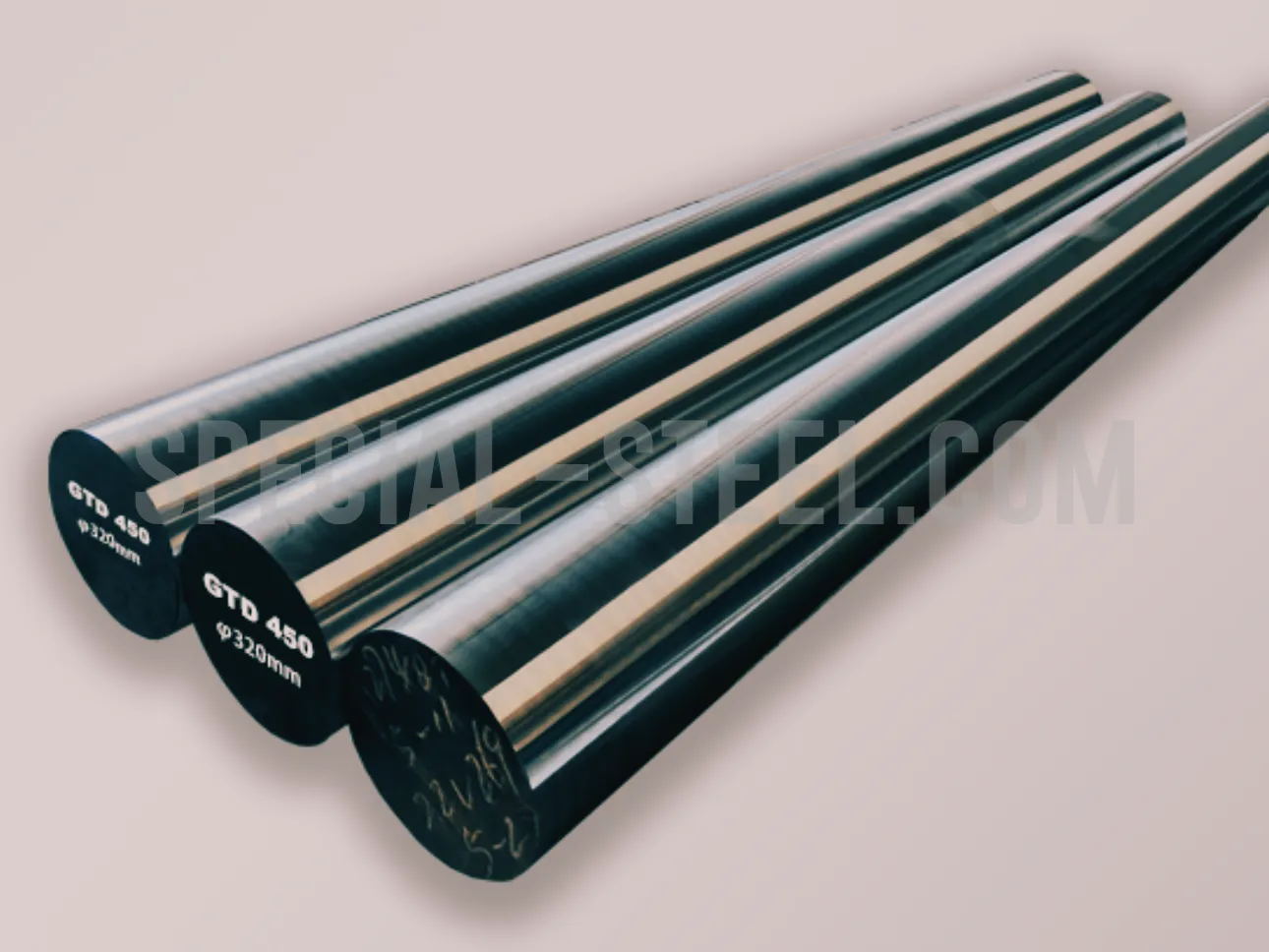

XM-25, GTD450, B50A789, 1.4594, X5CrNiMoCuNb14-5, Custom 450 martensitic age-hardenable stainless steel which exhibits very good corrosion resistance with strength. Used where high strength and good corrosion resistance, Turbine Blades, Pump Shafts , surgical Knife, medical Instrument

Table of Contents

What is XM-25, UNS S45000, 1.4594, X5CrNiMoCuNb14-5, Custom 450, B50A789?

Alloy C450, XM-25 martensitic age-hardenable stainless steel which exhibits very good corrosion resistance with strength. XM-25 alloy has a yield strength somewhat greater than 689 MPa in the annealed condition. A single-step aging treatment develops higher strength with good ductility and toughness. This stainless can be machined, hot-worked, and cold-formed in the same manner as other martensitic age-hardenable stainless steels. A particular advantage is ease of welding and brazing. XM-25 stainless is generally supplied in the annealed condition, requiring no heat treatment by the user for many applications. Mechanical properties will depend on the aging temperature selected. GTD 450 martensitic age-hardenable stainless steel. This alloy is relatively soft and formable in the annealed condition. A single-step aging treatment develops exceptionally high yield strength with good ductility and toughness. This stainless can be machined in the annealed condition, and welded in much the same manner as other precipitation hardenable stainless steels. Because of its low work-hardening rate, it can be extensively cold formed. The dimensional change during hardening is only about -0.001 in/in, which permits close-tolerance finish machining in the annealed state. GTD 450 stainless represents a significant advancement in the area of precipitation hardening stainless steels. It should be considered where simplicity of heat treatment, ease of fabrication, high strength and corrosion resistance are required in combination. Custom 450 stainless steel has very good corrosion resistance, high strength and good processing characteristics. A simple one-step aging treatment can make Custom450 obtain high strength, good plasticity and toughness.

Applications

- Aerospace & Turbine Components: Turbine blades, engine parts, and fasteners requiring oxidation resistance and creep strength at elevated temperatures.

- Oil & Gas: Downhole tools, valves, and offshore equipment exposed to sour service and chloride-rich environments.

- Power Generation: High-temperature bolts, steam turbine parts, and nuclear applications where stress corrosion cracking resistance is critical.

- Chemical Processing: Pumps, reactors, and fittings in aggressive acidic or alkaline media.

- Marine & Defense: Propeller shafts, submarine components, and naval hardware requiring seawater corrosion resistance and non-magnetic properties (e.g., 1.4594).

Chemical Composition (%)

| Grade | Chemical Composition WT % | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Cr | Cu | Ni | Mo | Nb | V | N | Ag | Pb | Sn | Ai | |

C450 |

≤0.05 | ≤1.00 | ≤1.00 | ≤0.03 | ≤0.03 | 14.0-16.0 | 1.25-1.75 | 5-7 | 0.5-1.0 | 0.35-0.75 | ||||||

Alloy 450 |

≤0.05 | ≤1.00 | ≤1.00 | ≤0.03 | ≤0.03 | 14.0-16.0 | 1.25-1.75 | 5-7 | 0.5-1.0 | 0.35-0.75 | ||||||

UNS S45000 |

≤0.05 | ≤1.00 | ≤1.00 | ≤0.03 | ≤0.03 | 14.0-16.0 | 1.25-1.75 | 5-7 | 0.5-1.0 | Nb 8 x (%C) | ||||||

XM-25 |

≤0.05 | ≤1.00 | ≤1.00 | ≤0.03 | ≤0.03 | 14.0-16.0 | 1.25-1.75 | 5-7 | 0.5-1.0 | Nb 8 x (%C) | ||||||

GTD450, B50A789 Class A, B, E, F, H |

0.025-0.045 | ≤1.00 | ≤1.00 | 0.025 | 0.005 | 14-16 | 1.25-1.75 | 6-7 | 0.5-1.0 | 0.4-0.75 / 14 x C Min | 0.1 | 0.03 | 0.005 | 0.005 | 0.1 | 0.05 |

| GTD450, B50A789 Class G | 0.03-0.05 | 0.3-0.8 | 0.2-0.5 | 0.020 | 0.005 | 14-16 |

1. 35-1.75 |

6.2-6.8 | 0.6-1.0 | 8xC-15xC | 0.1 | 0.03 | 0.005 | 0.005 | 0.1 | 0.03 |

ASTM A564 |

≤0.05 | ≤1.00 | ≤1.00 | ≤0.03 | ≤0.03 | 14.0-16.0 | 1.25-1.75 | 5-7 | 0.5-1.0 | Nb >8 x (%C) | ||||||

04Cr15Ni7Cu2MoNbVN |

0.03-0.05 | 0.2-0.5 | 0.3-0.8 | 0.02 | 0.005 | 14-16 | 1.35-1.75 | 6.2-6.8 | 0.6-1.0 | 8*C-15*C | 0.10 | 0.03 | 0.005 | 0.005 | 0.10 | |

X 5 CrNiMoCuNb 14 5 |

≤0.07 | ≤1.00 | ≤0.70 | ≤0.04 | ≤0.015 | 13.0-15.0 | 1.20-2.00 | 5.0-6.0 | 1.20-2.00 | 0.15-0.60 | ||||||

1.4594 |

≤0.07 | ≤1.00 | ≤0.70 | ≤0.04 | ≤0.015 | 13.0-15.0 | 1.20-2.00 | 5.0-6.0 | 1.20-2.00 | 0.15-0.60 | ||||||

Custom 450 |

≤0.05 | ≤0.50 | ≤0.50 | ≤0.03 | ≤0.03 | 14.50-16.50 | 1.25-1.75 | 5.50-7.00 | 0.50-1.00 | |||||||

Material Properties

GTD450 Mechanical properties acc. to GE B50A789

- Class E & F

- Tensile strength ksi, min: 146-175

- Yield Strength ksi, min: 132

- Elongation in 4D, %, min: 16

- Reduction of Area, %, min: 50

- Hardness: Brinell, 3000 kg Load: 302-363

- Impact, Room Temp., Charpy V-Notch (Ft.-Lbs.), min: 50

- Class H

- Tensile strength ksi, min: 140-175

- Yield Strength ksi, min: 120

- Elongation in 4D, %, min: 16

- Reduction of Area, %, min: 50

- Hardness: Brinell, 3000 kg Load: 302-363

- Impact, Room Temp., Charpy V-Notch (Ft.-Lbs.), min: 50

- Class G

- Tensile strength ksi, min: 180-195

- Yield Strength ksi, min: 120

- Yield Strength - 0.02% Offset (ksi), min: 140

- Elongation in 4D, %, min: 13

- Reduction of Area, %, min: 45

- Hardness: Brinell, 3000 kg Load: 380-415

- Impact, Room Temp., Charpy V-Notch (Ft.-Lbs.), min: 40

Longitudinal Room Temperature Tensile/Hardness/Impact Properties

- Class E, F, H

- Tensile strength ksi, min: 140-175

- Yield Strength ksi, min: 120

- Elongation in 4D, %, min: 16

- Reduction of Area, %, min: 50

- Impact, Room Temp., Charpy V-Notch (Ft.-Lbs.), min: 40

- Class G

- Tensile strength ksi, min: 180

- Yield Strength ksi, min: -

- Elongation in 4D, %, min: 5

- Reduction of Area, %, min: -

- Impact, Room Temp., Charpy V-Notch (Ft.-Lbs.), min: -

Short Transverse Room Temperature Tensile/Hardness/Impact Properties

XM-25 Mechanical properties acc. to ASTM A564

- H1150 <= 300 mm (T)

- Tensile strength Rm MPa: Min 860

- Yield Strength Rp MPa: Min 515

- A %: Min 12

- Z %: Min 35

- Hardness min: HR 26; HB 262

- H1150 <= 300 mm (L)

- Tensile strength Rm MPa: Min 860

- Yield Strength Rp MPa: Min 515

- A %: Min 18

- Z %: Min 55

- Hardness min: HR 26; HB 262

- H1100 <= 300 mm (T)

- Tensile strength Rm MPa: Min 895

- Yield Strength Rp MPa: Min 725

- A %: Min 11

- Z %: Min 30

- Hardness min: HR 30; HB 285

- H1100 <= 300 mm (L)

- Tensile strength Rm MPa: Min 895

- Yield Strength Rp MPa: Min 725

- A %: Min 16

- Z %: Min 50

- Hardness min: HR 30; HB 285

- H1050 <= 300 mm (T)

- Tensile strength Rm MPa: Min 1000

- Yield Strength Rp MPa: Min 930

- A %: Min 9

- Z %: Min 30

- Hardness min: HR 34; HB 321

- H1050 <= 300 mm (L)

- Tensile strength Rm MPa: Min 1000

- Yield Strength Rp MPa: Min 930

- A %: Min 12

- Z %: Min 45

- Hardness min: HR 34; HB 321

- H1025 <= 200 mm (L)

- Tensile strength Rm MPa: Min 1035

- Yield Strength Rp MPa: Min 965

- A %: Min 12

- Z %: Min 45

- Hardness min: HR 34; HB 321

- H1000 <= 300 mm (T)

- Tensile strength Rm MPa: Min 1100

- Yield Strength Rp MPa: Min 1035

- A %: Min 8

- Z %: Min 27

- Hardness min: HR 36; HB 331

- H1000 <= 300 mm (L)

- Tensile strength Rm MPa: Min 1100

- Yield Strength Rp MPa: Min 1035

- A %: Min 12

- Z %: Min 45

- Hardness min: HR 36; HB 331

- H950 <= 300 mm (T)

- Tensile strength Rm MPa: Min 1170

- Yield Strength Rp MPa: Min 1100

- A %: Min 7

- Z %: Min 22

- Hardness min: HR 37; HB 341

- H950 <= 300 mm (L)

- Tensile strength Rm MPa: Min 1170

- Yield Strength Rp MPa: Min 1100

- A %: Min 10

- Z %: Min 40

- Hardness min: HR 37; HB 341

1.4594, X 5 CrNiMoCuNb 14 5 Mechanical properties acc. to EN 10088-3

- +AT Dia. or Thick max 100 mm

- Tensile strength Rm MPa: max 1200

- P1070 Dia. or Thick max 100 mm

- Tensile strength Rm MPa: 1070-1270

- Yield Strength Rp MPa: Min 1000

- A %: Min 10

- Hardness: HB 360

- P1000 Dia. or Thick max 100 mm

- Tensile strength Rm MPa: 1000-1200

- Yield Strength Rp MPa: Min 860

- A %: Min 10

- Hardness: HB 360

- P930 Dia. or Thick max 100 mm

- Tensile strength Rm MPa: 930-1100

- Yield Strength Rp MPa: Min 720

- Akv J: Min 40

- A %: Min 15

- Hardness: HB 360

Physical Properties

- Density: ~8.20 g/cm³ (Ni-Cr-Mo base)

- Melting Range: 1350–1400°C

- Thermal Expansion (20–100°C): 12–14 × 10⁻⁶/°C

- Thermal Conductivity: 10–15 W/m·K

- Electrical Resistivity: ~1.10 μΩ·m

- Magnetic Response: Weakly magnetic (depends on processing)

Heat Treatment

Heat Treatment Specifications for Turbine Blade Alloys

XM-25 (Custom 450, UNS S45000) Solution Treatment:

- Temperature: 850–950°C (air or oil cooling)

- Purpose: Forms a uniform martensitic matrix with dissolved carbides.

- Aging (Precipitation Hardening):

- H900: 480°C × 1–4h (air cooling) → Max strength (σ₀.₂ ≥ 1200 MPa)

- H1150: 620°C × 4h (air cooling) → Better toughness & stress corrosion resistance

- Key Notes:

- Avoid prolonged exposure at 475°C (risk of embrittlement).

- Turbine Blade Use: Compressor blades or low-pressure stages (≤400°C).

GTD450 (Ni-Cr-Mo Superalloy for Gas Turbines) Solution Treatment:

- Temperature: 1050–1100°C (water/quench cooling) → Full austenitization.

- Aging (Dual-Stage):

- Primary Aging: 720–750°C × 8h (air cooling) → γ' (Ni₃Al/Ti) precipitation.

- Secondary Aging: 620–650°C × 8h (air cooling) → Strengthens Ni₃(Al,Ti) phases.

- Key Notes:

- Optimized for high-pressure turbine blades (≤700°C).

- Fast cooling after solution treatment avoids grain-boundary carbides.

B50A789 (Ni-Fe-Cr Superalloy, Similar to 718 Variant) Solution Treatment:

- Temperature: 950–980°C (water quenching) → Dissolves δ-phase and carbides.

- Aging (Step Aging):

- Standard Aging: 720°C × 8h → Furnace cool to 620°C × 8h (air cooling).

- Direct Aging (DA): Skip solution treatment → Better grain-boundary strength.

- Key Notes:

- Dominant strengthening via γ'' (Ni₃Nb) precipitates.

- Used in high-pressure turbine blades & bolts (≤650°C).

1.4594 (X5CrNiMoCuNb14-5, UNS S45500) Solution Treatment:

- Temperature: 850–950°C (fast cooling) → Martensitic transformation.

- Aging:

- H900: 480°C × 4h → High strength (σ₀.₂ ≥ 1100 MPa).

- H1050: 550°C × 4h → Balanced strength & corrosion resistance.

- Key Notes:

- Cu/Nb additions enhance aging response.

- Suitable for compressor blades (limited to ≤450°C due to tempering effects).

Summary for Turbine Blade Applications

| Alloy | Solution Treat (°C) | Aging Process | Strengthening Mechanism | Max Service Temp |

|---|---|---|---|---|

| XM-25 | 850–950 | 480°C (H900) or 620°C (H1150) | Cu/Nb + Martensite | 400°C |

| GTD450 | 1050–1100 | 720°C + 620°C dual aging | γ' (Ni₃Al/Ti) | 700°C |

| B50A789 | 950–980 | 720°C → 620°C step aging | γ'' (Ni₃Nb) | 650°C |

| 1.4594 | 850–950 | 480–550°C single aging | Cu/Nb + Tempered Martensite | 450°C |

Critical Considerations for Turbine Blades: GTD450 & B50A789: Require controlled cooling to avoid η-phase or σ-phase embrittlement.

- XM-25 & 1.4594: Limited to lower-temperature stages due to martensite tempering.

- Post-Weld Heat Treatment (PWHT): Necessary for welded repairs (e.g., 1.4594 at 580–620°C).

- For specific blade designs (single-crystal vs. polycrystalline), aging parameters may require adjustments. Let me know if you need further details!

Processing Performance

XM-25 (Custom 450, UNS S45000) Welding Performance

Weldability: Fair to good (similar to 17-4PH)

- Processes: GTAW (TIG) and GMAW (MIG) with matching filler (e.g., ER630).

- Challenges:

- HAZ cracking risk due to martensite formation; preheat (150–200°C) and post-weld aging (H900 or H1150) required.

- Avoid high heat input to prevent grain coarsening.

- Machining Performance

Machinability: Moderate (40% of free-cutting steel). - Tools: Carbide or ceramic tools with high rigidity.

- Tips:

- Use low-speed, high-feed rates to avoid work hardening.

- Solution-annealed condition is easier to machine than aged.

- Hot Working (Forging/Rolling)

Hot Work Range: 950–1150°C (avoid <900°C to prevent cracking). - Key Notes:

- Forge in solution-annealed condition; rapid cooling post-forging to retain ductility.

GTD450 (Ni-Cr-Mo Superalloy) Welding Performance

- Processes: Electron beam (EBW) or laser welding (LBW) preferred; TIG possible with ERNiCrMo-3 filler.

- Challenges:

- Strain-age cracking during post-weld heat treatment (PWHT).

- Requires stress-relief annealing (800°C × 2h) before aging.

- Machining Performance

Machinability: Difficult (20% of free-cutting steel). - Tools: Polycrystalline diamond (PCD) or coated carbide.

- Tips:

- High-pressure coolant to manage heat.

- Machine in annealed condition; aged state drastically reduces tool life.

- Hot Working

Hot Work Range: 1050–1200°C (narrow window). - Key Notes:

- Slow cooling post-forging to avoid quench cracking.

- Limited to isothermal forging for complex blade geometries.

Weldability: Poor (high crack sensitivity).

B50A789 Welding Performance

- Weldability: Fair (better than GTD450 but worse than 304 stainless).

- Processes: TIG with ERNiFeCr-2 filler; friction welding for blades.

- Challenges:

- Liquation cracking in HAZ; use low heat input and fast travel speed.

- Post-weld aging (720°C × 8h) mandatory to restore properties.

- Machining Performance

Machinability: Moderate (30% of free-cutting steel). - Tools: Carbide with TiAlN coating.

- Tips:

- Avoid interrupted cuts (work hardening risk).

- Drilling requires pecking cycle to clear chips.

- Hot Working

Hot Work Range: 950–1100°C. - Key Notes:

- Superplastic forming possible for hollow blades.

- Forging below 900°C causes delta-phase embrittlement.

1.4594 (X5CrNiMoCuNb14-5, UNS S45500) Welding Performance

- Weldability: Good (similar to 17-4PH).

- Processes: TIG with ER630 filler.

- Challenges:

- Martensite formation in HAZ; post-weld aging (480–550°C) essential.

- Machining Performance

Machinability: Moderate (35% of free-cutting steel). - Tools: Carbide with high rake angles.

- Tips:

- Higher speeds than austenitic steels but lower than carbon steels.

- Hot Working

Hot Work Range: 900–1100°C. - Key Notes:

- Fast cooling post-forging to prevent σ-phase formation.

Comparative Summary for Turbine Blade Manufacturing

| Property | XM-25 | GTD450 | B50A789 | 1.4594 |

|---|---|---|---|---|

| Weldability | Fair-Good | Poor | Fair | Good |

| Filler Metal | ER630 | ERNiCrMo-3 | ERNiFeCr-2 | ER630 |

| Machinability | Moderate | Difficult | Moderate | Moderate |

| Hot Work Range | 950–1150°C | 1050–1200°C | 950–1100°C | 900–1100°C |

| Key Risk | HAZ cracking | Strain-age crack | Liquation crack | σ-phase |

General Recommendations for Turbine Blades: Welding: Use low-heat-input processes (EBW/LBW for GTD450/B50A789).

- Machining: Prioritize tool coatings and coolant for Ni-based alloys.

- Hot Working: Strict temperature control to avoid embrittlement phases.

- For specific blade designs (e.g., single-crystal vs. forged), further process optimization may be needed. Let me know if you need deeper insights!