1.3813, X40MnCrN19 K, X40MNCR18K, 1.3817

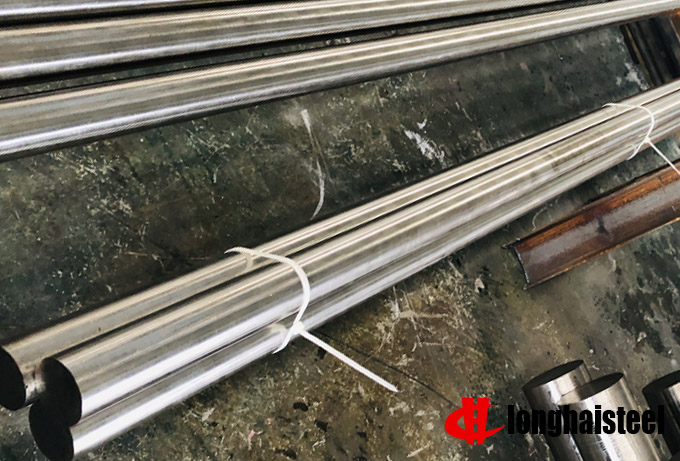

X40MnCrN19K, also designated as 1.3813, is a high-performance non-magnetic steel known for its excellent rust and acid resistance. This grade is commonly supplied in a hot-cold-formed condition, meeting specifications such as TLV 9384.01, SEW 390, and DIN standards. Its unique composition ensures durability in corrosive environments while maintaining non-magnetic properties, making it suitable for specialized industrial applications.

What is 1.3813, X40MnCrN19 K, X40MNCR18K, 1.3817?

Applications

X40MnCrN19K, 1.3813 non-magnetic steels, rust and acid resistant. 1.3813 is often supplied in a hot-cold-formed version. In this treatment state, 1.3813 has a tensile strength of 830 – 1030 N/mm² and a yield point of at least 390 N/mm² at room temperature.Area of application connecting parts, mechanical engineering, mechanically and thermally highly stressed components in shipbuilding, mechanical engineering and vehicle construction as well as in electrical engineering These rolled round bars intended for the manufacture of shafts, arbors, pins and similar parts, acc. to TLV9384.01 SEW 390, DIN Spec.

Chemical Composition (%)

| Grade | Chemical composition WT % | ||||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | N | |

X40MnCrN19K, 1.3813 |

0.3-0.50 | Max 0.50 | 18-20 | Max 0.05 | Max 0.015 | 3.0-5.0 | 0.08-0.12 |

X40MNCR18K, 1.3817 |

0.3-0.50 |

Max 1.00 |

17-19 |

Max 0.06 |

Max 0.015 | 3.0-5.0 | Max 0.10 |

Material Properties

Cold Working

- Tensile strength Rm MPa: Min 850-1250

- Yield Strength Rp MPa: Min 600

-

Akv J: Min 90

- A %: 35

Hot working

- Tensile strength Rm MPa: Min 830-1030

- Yield Strength Rp MPa: Min 390

- Akv J: Min 124

- A %: Min 40

Quenched

- Tensile strength Rm MPa: 740-930

- Yield Strength Rp MPa: Min 290

- Akv J: Min 124

- A %: Min 45

Cold Drawn

- Tensile strength Rm MPa: 850-1250

- Yield Strength Rp MPa: Min 550

- Akv J: Min 90

- A %: Min 20

- Z %: Min 35

- Hardness: 260-360 HB

Physical Properties

| Temp(℃) | GPa | MTEC | W/m·℃ | J/kg·℃ | Ωmm²/m | kg/dm³ | v |

|---|---|---|---|---|---|---|---|

| 400.0 | - | 18.70 | - | - | - | - | - |

| 300.0 | - | 17.90 | - | - | - | - | - |

| 200.0 | - | 17.10 | - | - | - | - | - |

| 100.0 | - | 16.00 | - | - | - | - | - |

| 20.0 | - | - | 14.00 | - | - | - | - |

| 20.0 | - | - | - | - | 0.70 | - | - |

| 20.0 | - | - | - | - | - | 7.70 | - |

| 20.0 | 195.00 | - | - | - | - | - | - |